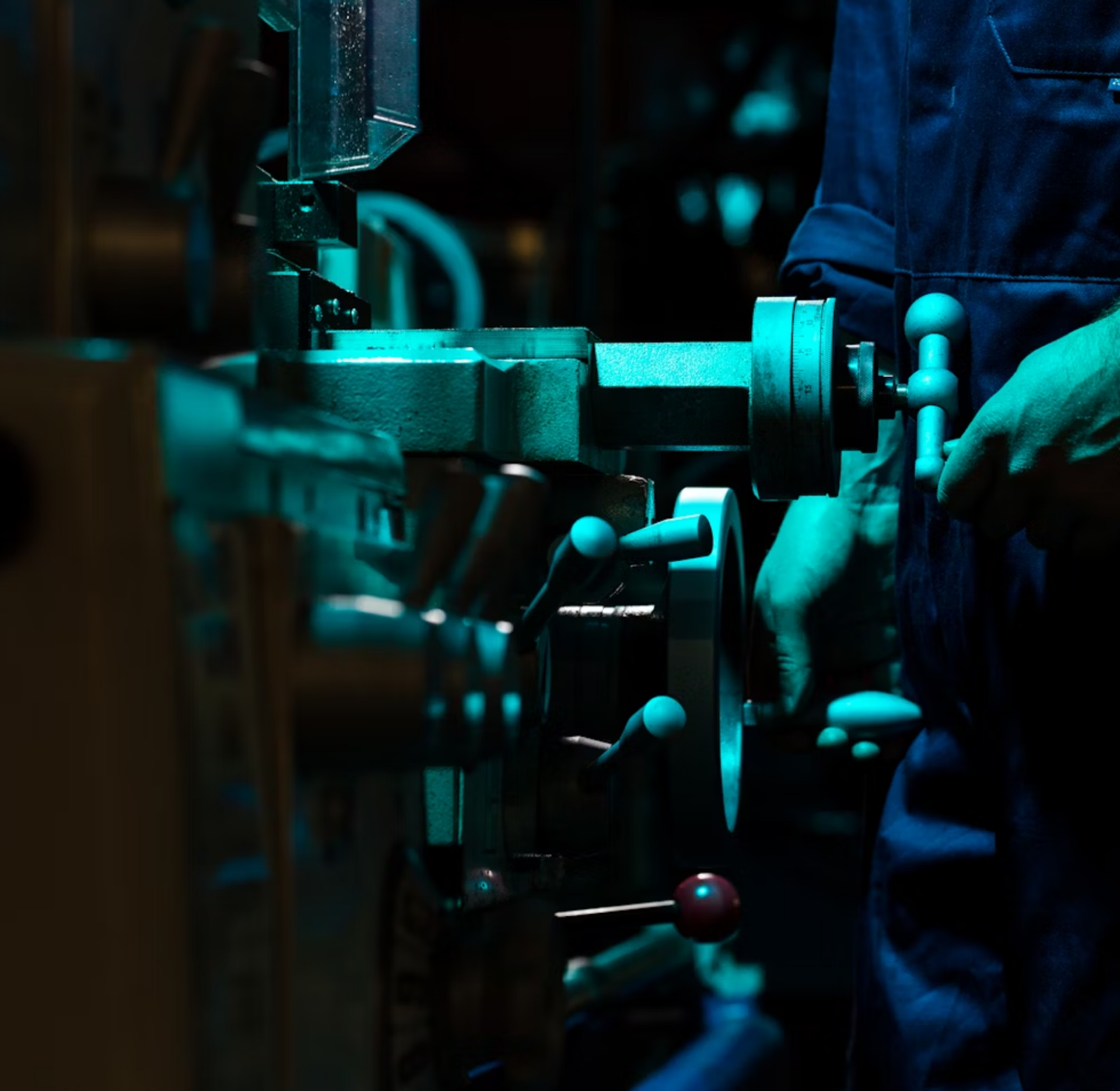

Tailored Solutions for Critical Components

Whether starting from an existing part, outdated blueprints, or a conceptual idea, we carry out the entire design and engineering process from scratch to deliver an efficient, durable result aligned with your industry’s quality standards.

What do we do?

- Reverse engineering: We scan or analyze existing parts to replicate, improve, or adapt them to new operational environments.

- Custom 3D Design: We use professional software (SolidWorks, AutoCAD, Inventor, etc.) to create precise, functional, and manufacturing-ready models.

- Structural Analysis (FEA): We evaluate areas of highest stress, deformation, or fatigue, optimizing geometries and materials to ensure strength without overengineering.

- Technical documentation: We deliver drawings in standard ISO, ANSI, or your company’s required formats, including tolerances, materials, treatments, and finishes.

- Manufacturing compatibility: We validate that each design is compatible with our CNC, welding, cutting, and assembly processes, reducing rework and production errors.

- On-site support: Our team can assist with installation, performing fine adjustments, calibrations, and functional testing to ensure a perfect assembly either on-site or in the field.

Common applications

- Replacement or redesign of damaged or discontinued industrial components.

- Improvement of existing equipment for greater durability, efficiency, or safety.

- Manufacturing of custom-designed tooling, fasteners, or moving parts.

- Adaptation of parts to imported machinery or specific production lines.